Welcome Back to Our Series on Rotating Equipment

In our last chat, we tackled the nitty-gritty of aligning pre-installed rotating equipment, like pump sets. If you missed it, check out our Previous Post for some insightful tips. Today, let’s roll up our sleeves and get into the very foundation of proper installation—the base plate.

Why Are Jack Bolts Important?

At Anfield Industrial Solutions, we’ve been conducting numerous shaft alignments recently. One observation we’ve made is that not all motors, gearboxes, and similar equipment have jack bolts on their corners. This might seem like a minor detail, but it can significantly impact the alignment process.

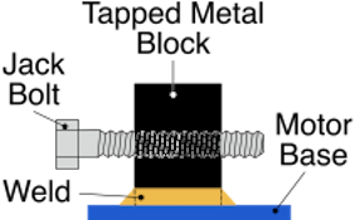

Imagine you’re aligning a pump-motor set. You’ve checked and adjusted for any soft-foot issues, adding or removing shims under each of the motor’s four feet to achieve vertical alignment with the pump shaft. Now, it’s time to set your horizontal alignment. You’ve loosened all the hold-down bolts and made your left-to-right adjustments to obtain horizontal alignment, only to have it go out of alignment when you tighten the hold-down bolts. This is where jack bolts are invaluable.

Benefits of Jack Bolts:

- Stabilize Movement: They freeze left-to-right movement during hold-down bolt tightening

- Precise Adjustments: They allow for controlled, minute adjustments

- Leverage and Control: They provide the leverage to create and hold a twist movement during bolt tightening.

- Consistency: They offer a reference point for alignment when a motor is replaced

So why aren’t they on every motor and gearbox? It’s a good question. Perhaps some motors are considered too small to warrant the effort of welding jack bolts to the base. While the reasons may vary, we strongly recommend including them in your specifications for new purchases and starting a program to add them to existing equipment during the next scheduled alignment.

Visual Aid

We’ve included a couple of schematics of jack bolts to help visualize their setup and utility. We hope you find this useful in your ongoing journey towards greater equipment reliability.