Recently, Anfield Industrial Solutions stumbled upon a shaft laser alignment project that got us thinking: do those pre-assembled rotating equipment packages that come neatly mounted on skids arrive with their shafts already aligned? Is it important to know? How do you know the equipment is aligned? And does any of that make a difference to the actual installed performance of the equipment? Let’s dive into this intriguing question.

Why Alignment Matters:

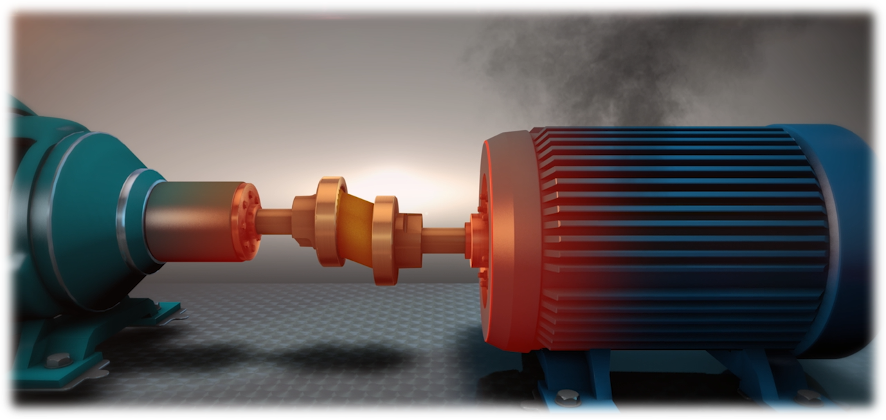

We all know the havoc misalignment can wreak on rotating equipment – from operational issues, increased wear and tear, reduced efficiency, and even catastrophic failures. So, it’s critical to ensure that our rotating equipment starts off on the right foot, or should I say, the right shaft.

Visual Inspection:

First and foremost, inspecting the equipment and skid upon delivery is essential. Do this even if you have received the manufacturer’s certified quality certificate that the alignment has been performed to their specified tolerance. Check for any scraps, dings, chipped paint, or signs of rough handling during transit. And don’t forget to look where the equipment feet are attached to the skid – those shims can tell you a lot about the alignment job.

Installation Considerations:

Even if the manufacturer swears up and down that your equipment is aligned to perfection, there are still plenty of variables to consider during installation. Is your concrete foundation both flat and level? Are you installing directly to the concrete or utilizing leveling nuts? And what’s the plan if something goes awry down the line?

Understanding Flatness and Levelness:

Let’s clear up a common misconception: flatness and levelness aren’t the same thing. While level refers to a surface that is parallel to the Earth’s surface and perpendicular to the direction of gravity, flatness refers to a surface that is smooth without bumps, depressions, or significant irregularities and in the same plain. Both factors come into play when setting equipment on a foundation.

The Importance of Laser Alignment:

We recommend laser alignment to ensure precise alignment and optimal performance. This method provides accurate measurements and allows adjustments to be made quickly and efficiently. Trust me, you’ll thank yourself later for investing in this level of precision.

Take Action:

Don’t leave the alignment of your rotating equipment to chance. Give us a shout at Anfield Industrial Solutions (866-798-5033) to chat about your alignment needs or schedule a consultation. Let’s keep those shafts spinning smoothly!